Field of Applications

- Drinking water supply installation for cities and rural districts.

- Fully automatic domestic water supply installation.

- Pressure boosting installation.

- Service water supply installations for industry and commerce.

- Cooling water circulation systems.

- Lowering the ground water level on building sites.

- Containing the ground water level in mines.

- Air conditioning installations.

- Ornamental fountain pumps etc.

Submersible Pumps

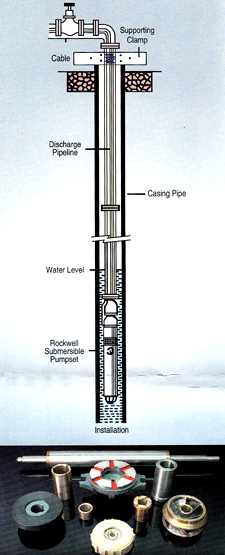

Rockwell submersible Pumps are built together as single or multistage, centrifugal pumps directly coupled with squired cage electric motors. Normal operating voltage 415 volts, 50 C/S Phase supply. The coupled unit is freely suspended and lowered with the column pipe below the lowest expected water level in the well. The decisive factor in the efficiency of the pump design is the reliability of the electric motor. The Rockwell submersible motors are of the wet type, i.e. they are completely filled with water and a special wire with water proof insulation is used for the stator winding.

Motor and pump shafts are supported in water lubricated, plain bearing, and the axial thrust is not countered by balancing device or holes in the impeller but by a Mitchell Tilting pad Bearing, also lubricated with water.

The motor is totally enclosed, at its upper end there is rigid seal and below the thrust bearing there is a diaphragm that tends to equalize internal and external pressure by yielding when the heal from the windings cause the water in the motor to expand. The top and-bottom seals are provided to prevent any exchange of liquids.

The discharge connection located at the top of the pump incorporates a non-return value and can be supplied with either flanged or screwed connection. The pump suction housing is located between the pump and motor and provided with a perforated strainer. The cable or cables are lead out of the motor through cable sealing glands and protected against accidental damage from knock or shocks, by means of metal cable sheaths along the length of the pump body. The pump shaft is connected to the motor by muff type coupling.

The total efficiency of Rockwell pumps is superior to conventional deep well turbine pumps at a much cheaper cost, namely capital cost, running cost, maintenance cost, installations cost etc.

Range

- 100mm (4") BOREWELL and more

Discharge from 20-425 LPM & Head up to 250 Meters

- 150mm (6") BOREWELL and more

BP-142 - 50 to 380 LPM & Heads up to 200 Meters.

RP-150 - 200 to 1500 LPM & Heads up to 150 Meters

- 200mm (8") BOREWELL and more

RP-200 - 300 to 3000 LPM & Heads up to 150 Meters.

- 300mm (12") BOBEWELL and more

RP-225 & RP-250 - 1500 to 5100 LPM & Heads up to 120 Meters.

- Manufactured & Tested as per IS: 8004 1989 & IS: 9283 - 1995, as amended.

- On demand pumps in special materials can be supplied, depending on the nature and quality of water.

- Motors can be wound for special voltage on special demand.

Advantages

- Immune to frost, because of installation depth below frost level.

- Can be easily installed in crocked wells.

- Economic in operation, because of high overall efficiency of pumping set.

- Reliable in operation, because of well proven design and construction.

- Require no maintenance, because it is a glandless construction and is water lubricated.

- Low noise level, because of journal bearings.

- No loss of suction, because installation is below the water level.

- Can also be installed horizontally in certain cases.